Industrial automatic coating line Powder coating production line Precision roller coating varnish spray production line

Product spotlights

System Overview

-

Provides a complete, automated solution comprising pretreatment, drying oven, powder coating booth, and curing ovens.

-

Engineered for efficient and highly durable surface finishing.

Operational Flexibility

Customization & Certification

-

Features a range of customization options to meet specific production needs.

-

Manufactured in compliance with high-quality standards, holding ISO9001, ISO14001, ISO45001, and CE certifications.

Target Industries

Manufacturer Expertise & Support

-

Backed by over 10 years of specialized industry expertise.

-

Provides comprehensive one-stop services, from initial design to after-sales support.

Product description

The Precision Roller Spray Painting Line is summarized below in a structured format for clarity, highlighting its key aspects based on the provided description. This system is optimized for manufacturing efficiency and quality in coating processes.

- Ideal Application: Suitable for medium-volume processing in manufacturing environments, particularly for workpieces like automobile wheels and ovens where consistent coating is essential.

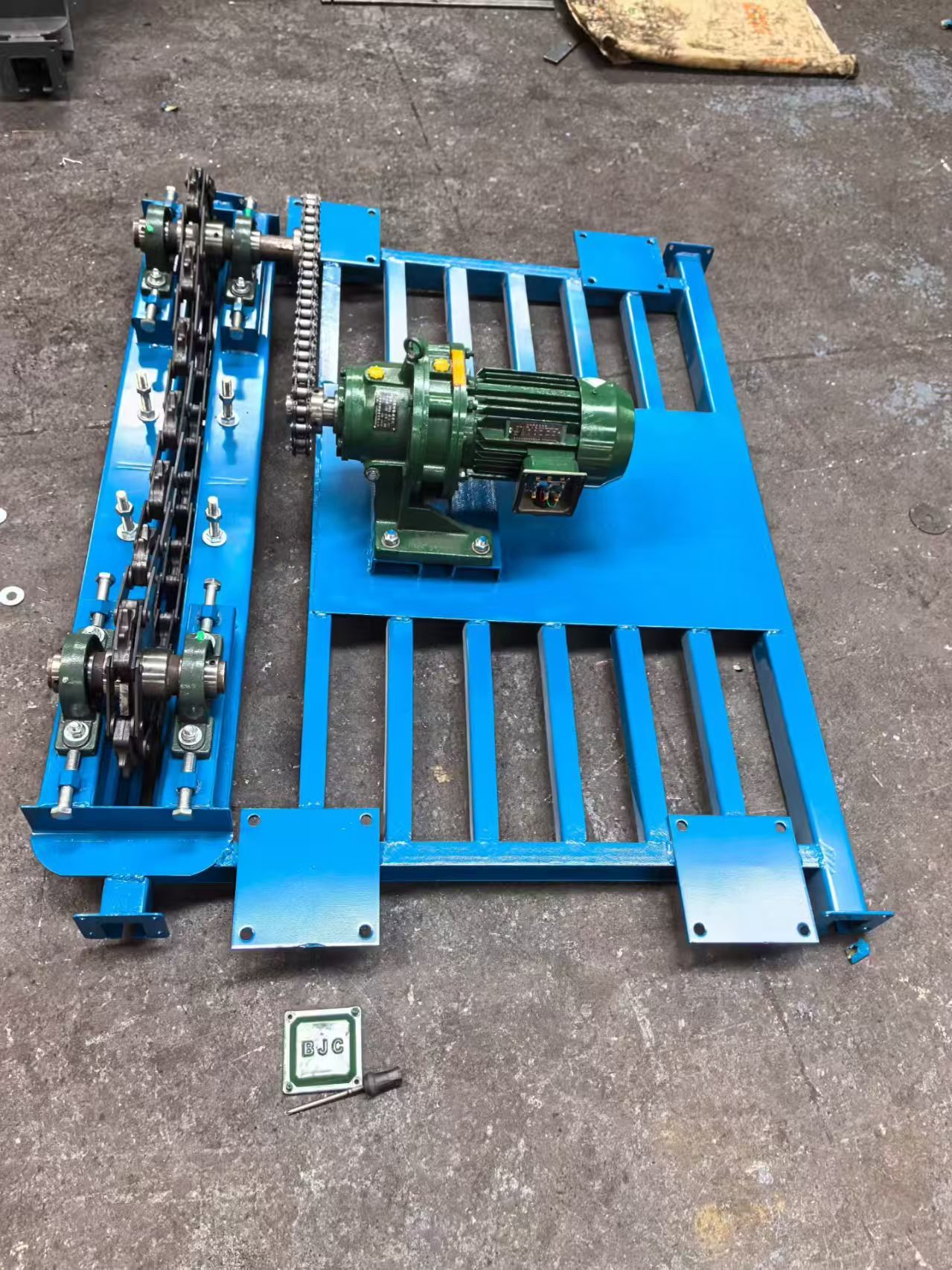

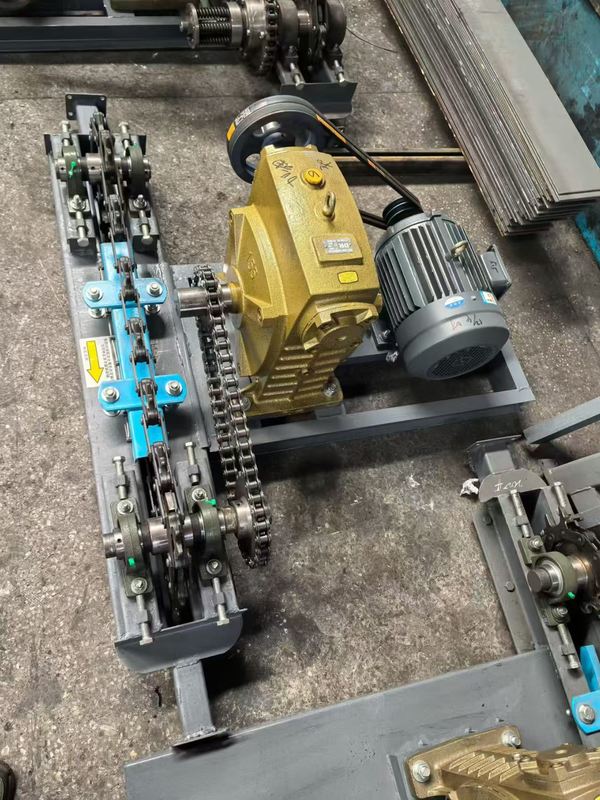

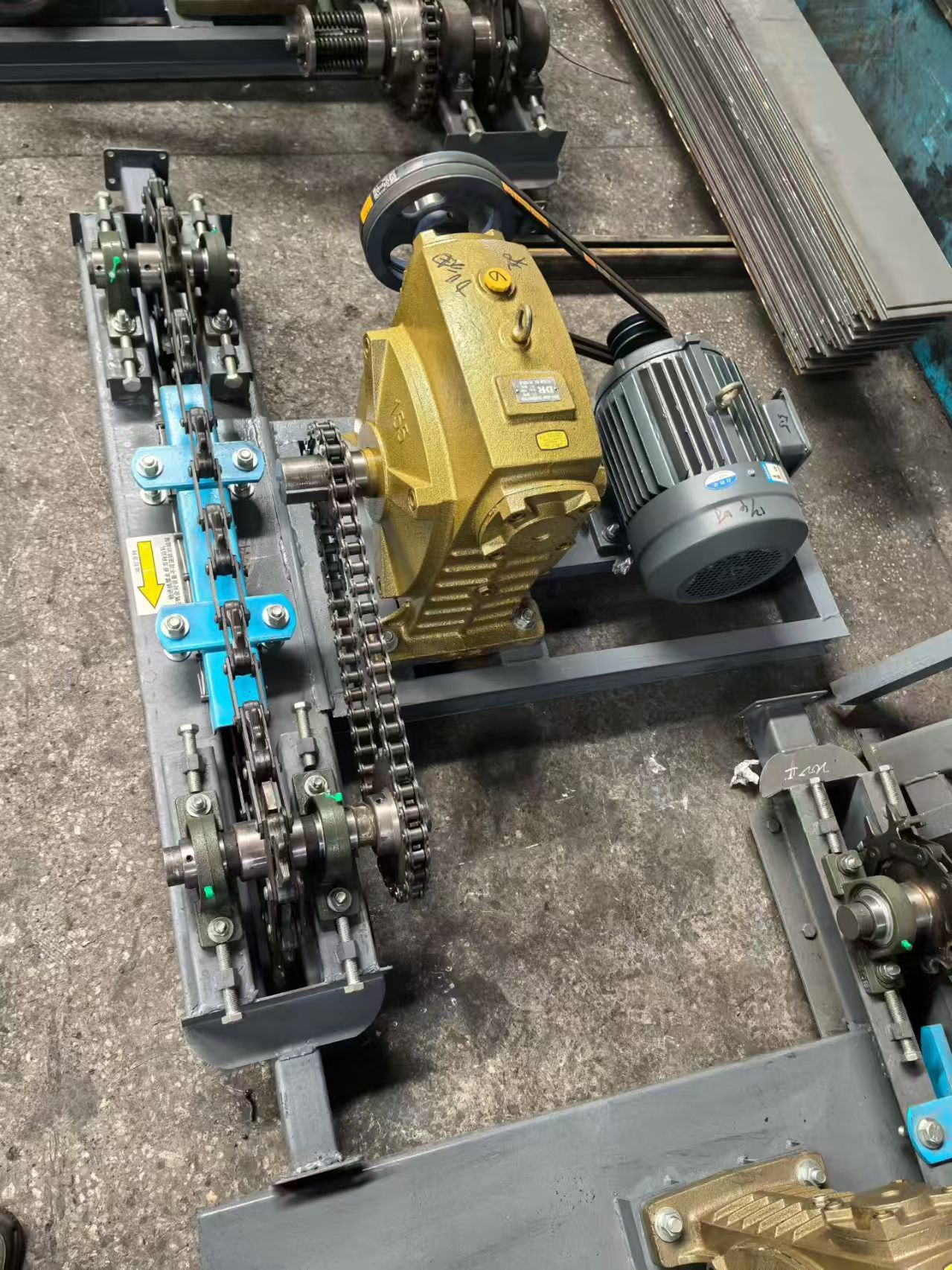

- Core Components: Includes pre-treatment equipment for surface preparation, spray painting equipment for application, an oven for curing, a heat source system for temperature management, an electronic control system for automation, and a roller conveyor line for seamless transport.

- Workpiece Transport: Workpieces are moved on tooling fixtures through the spraying area, ensuring precise positioning and uniform coverage during the coating process.

- Operational Features: Operates with a PLC-based control system for automation, stepless speed adjustment for variable processing rates, multiple induction probes for accuracy in detection, and manual control buttons to enhance operational flexibility.

- Performance Benefits: Delivers high-quality, efficient coating processes by integrating advanced controls and reliable components, minimizing waste while maximizing output.

Product Details

| Machine Type |

Roller Coating line |

| Warranty of core components |

1 Year |

| Core Components |

Motor |

| Place of Origin |

Guangdong, China |

| Warranty |

1 Year |

| Key Selling Points |

Automatic |

| Applicable Industries |

Automobile Wheels, Turntables, Ovens Machinery Repair Shops, Manufacturing Plant, Construction works |

| Weight (KG) |

200 |

| Substrate |

Steel |

| Condition |

New |

| Coating |

Painting |

| Brand Name |

CoatTech |

| Voltage |

380V |

| Power |

5KW |

| Dimension (L*W*H) |

AS YOUR NEEDS |

| Function |

Spraying Coating |

| Color |

Customizable |

| Weight |

24kg |

| Voltage |

380v |

| Power |

75kw |

| Size |

24330*6300*3700mm(customizable) |

| Product name |

Roller Coating line-1 |

| Keywords |

Painting Line |

| |

|

| Packaging and Delivery |

|

| Selling Units |

Single item |

| Single package size |

60X50X40 cm |

| Single gross weight |

50.000 kg |

| Lead time |

|

| Quantity (sets) |

>1 |

| Lead time (days) |

15 |

The roller coating line is suitable for medium-volume, regular workpieces; such as automobile wheels, turntables, ovens, etc.

As a kind of automated spraying equipment, the roller spray painting line mainly consists of six major components:

pre-treatment equipment, spray painting equipment, oven,heat source system, electronic control system, roller conveyor line, etc.

It can place the workpiece on the tooling fixture of the conveyor line, and send the workpiece into the spraying area

for spraying through the rotation of the roller. The roller line generally,uses an accumulation system. Each station has

a manual control button, and each completed workpiece can be lowered to the spraying area. Processed at the next station.

The entire line adopts PLC control, stepless speed adjustment, and is equipped with multiple induction probes and control buttons.

The electric roller is a new type of driving equipment in which the motor and reducer are placed inside the roller body.

It is mainly used in fixed and mobile belt conveyors,replacing traditional motors and separate drive equipment with

reducers outside the driving roller.

Peace Environmental Protection always adheres to the core principle of "quality first, honest service" and provides

excellent solutions for customers in the field of environmental protection equipment. The factory is located in

Guangzhou City, Guangdong Province.

The company's main products include environmental protection equipment such as spray booth,coating line,painting line

and waste gas and wastewater treatment,if you have any inquiry,please leave the inquiry here directly,will be respond to you within 12 hours

We will make the exact Design Drawing,Design Case in words,and Quotation in detail,just waiting for you leave the message here.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!